The Fat Controller gives the round up on our latest product to hit the shelves; Sugar Artists’ Acrylic.

Sugar has been available in Australia for a couple of months and it’s just dropped across the USA and Europe. Now that it’s getting into the hands of writers I thought I’d drop you an update to fill you in on the background of this product.

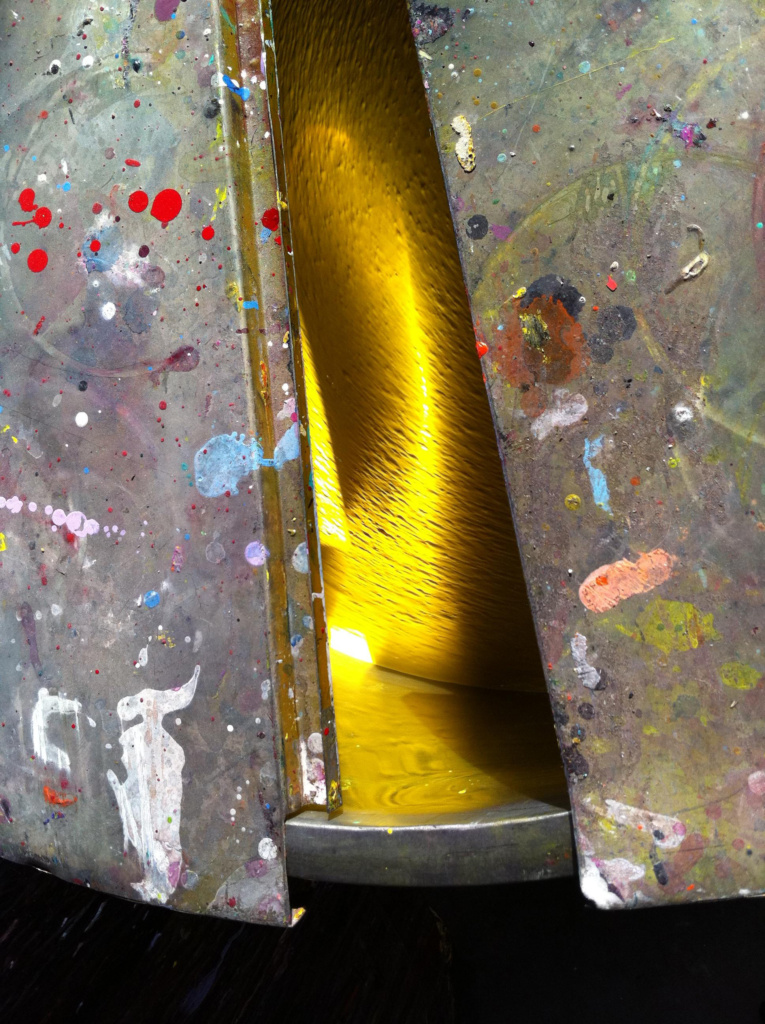

In the grand scheme of things Sugar has been three years in the making, although we took just over a year off in the middle of that to focus on the construction of our new factory. It’s a low-pressure matt paint. A water/alcohol hybrid product that’s made from harvested sugarcane. The goal was to create a healthier product that has less VOC’s or harmful solvents than other spray paint products, while still performing as well as other premium low pressure matt paints. It wasn’t an easy feat.

We were also able to create Sugar without the overspray or dustiness that matt spray paint typically exhibits, leaving you with the ability to create really clean lines. Compare some other matt paints to Sugar and you’ll see what I mean, it’s really impressive.

It’s completely different to anything we’ve produced before and I feel like writers and artists that prefer using low-pressure matt paint will love it. You’ll be blown away by the vibrancy of the colours, the cleanliness of the lines, the crisp matt finish and how well the paint levels on the surface. The control with which you can do detailed work and then obviously how long your work will last due to the updated pigments. It’s nothing short of amazing and I’m really excited we were able to get this out there. I believe writers are really going to love using it, as much for the performance aspects as for the health and environmental factors.

Because of the water and alcohol used in the product, it’s not as flexible in extreme weather as Ironlak, Yard Master or Reload so if you’re painting in extreme heat or cold we’d suggest you stick with those. Between -2 and 27 degrees Celsius Sugar works amazingly well. It may work fine in colder temps but we just don’t have enough test data to recommend it at this point.

We could have made Sugar an all-temperature paint by reducing the water and alcohol content which isn’t something we wanted to do. I can really see this paint appealing to artists that put in a lot of detail; people like DOES, VANS, SOFLES, EWOK or MR WANY. Due to the lower smell it’s great for those working indoors or in the studio. It’s not going to be for everyone which is why we have other products like Ironlak and Yard Master. We’ve got something to meet everyone’s needs.

Most of our competitors talk about innovation, which I feel is more marketing spin and gimmicks than substance. This is something that hasn’t been done before. No one has innovated like this before and it will be a long time before someone does something this big in our industry again. (though I’m sure someone will copy us in record time now that we’ve paved the way).

There were a few really big hurdles to overcome in juggling the balance between performance and health and to get from 80% complete to 90% complete was tough. To take it the whole way felt like it took forever. That last 10% was a six month process for us and one that almost drove me mad.

There are still a few minor things that could be improved such as performance in hot weather. Our view is a simple one; nothing is perfect and everything can be improved. We use the same approach to developing products as we do to progressing as writers: constant evolution. If you fall in love with your last piece you become stagnant and start fall off, if you stay hungry you’re always striving to do a better piece than the last one. So while some may rest on their laurels, we don’t. Even if we believe our products are the best in the market (and we do), we also believe we can make them better and give writers even better tools to express themselves.

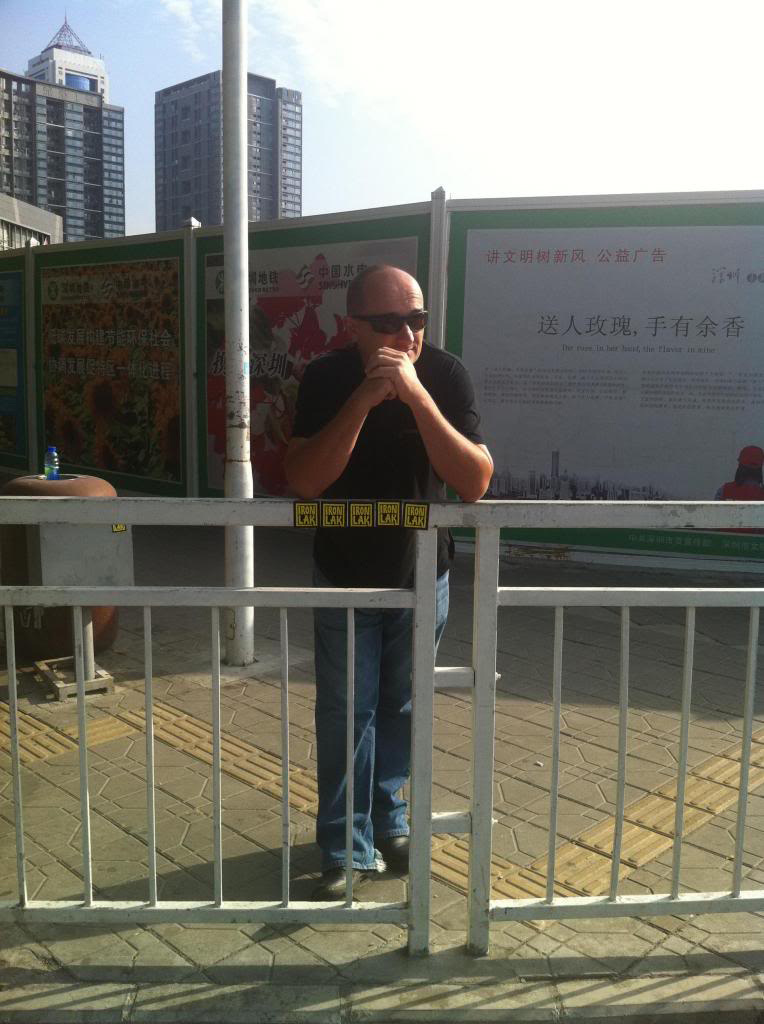

To get Sugar finished TUESY and I would travel to China often – for me it was every month – trying to finalise this product. We had a few trial runs and false starts along the way where we thought we had it and we’d do a small production run and see that something wasn’t quite right. We’d hand it to our Family for feedback and they’d bring up other aspects we could improve. After several trial runs, we knew we were close. In late November we went over to China to put on the finishing touches and oversee mass production. It was exciting and rewarding. It was also a huge weight off our shoulders to be so close to the finish line.

After shipping we always do a final QC (Quality Control) check before we release something to the public so when the paint arrived in Australia, we went out and put it through its paces. Did all the checks and balances, then we did it again just to be sure by painting a couple of quick pieces.

Lastly, TUESY got TREAZY and SOFS out to rock some pieces with it. They gave it the thumbs up (check it out here). In the past couple of months since it has been available, we’ve had so many really elite writers tell us it’s the best low-pressure paint they’ve ever used.

Sometimes we cop flack from haters for producing our paint in China, but we’re one of the few paint companies who actually own our own factory which helps with product development, quality control and innovation. We’re also one of the very few, if not the only paint brand that’s owned and run by writers. The thing about China is that it does have a rich history of innovation from paper making, printing, alcohol and even early uses of lacquer, so our view is; why can’t an Australian graffiti company with its own factory in China pioneer new products to the art world and continue that rich tradition. Today so many quality products are produced in China from iPhone’s to designer footwear, so where our products are made should have no bearing on the innovation we pioneer or the quality we produce.

Our job is done for now, the next step is all yours. Enjoy!

More info:

Sugar Colour Chart

Like us on Facebook

Follow us on Instagram

Follow us on Tumblr